Table of Contents

If you’ve heard the term DTG being bandied around but are secretly clueless as to what it is, don’t worry; we a) won’t tell anyone your secret and b) have the lowdown you need to impress everyone with your newly in-depth knowledge.

So what in the world is DTG printing? Well, in case you didn’t know, DTG stands for Direct to Garment printing. DTG printing is a method where digital images are printed directly onto textiles.

Picture it this way: your home printer got bored of churning out tax forms and decided to have a fling with your wardrobe. Your favorite designs, symbols, logos – you name it – can be imprinted straight onto your garments. It’s like having a personal artist at your beck and call, ready to whip up your wearable masterpieces.

And it’s not just about individual style, oh no. Does this story sound familiar to you? You’re running a local soccer team, maybe you work with a spirited bunch of little leaguers or a hard-hitting women’s rugby squad. They’ve got the passion, they’ve got the skills, but they’re missing one thing: a killer team uniform. With DTG, you can give your team that unique edge.

DTG printing is ideal for creating intricate, vibrant designs on sportswear. It gives you the freedom to print customized jerseys with player names, numbers, and team emblems. So, each member gets to wear their identity on the field – that’s a big morale booster and team spirit inducer, right there.

What’s more, the print quality of DTG is superior. The prints are sharper, with great detail, ensuring your team’s logo stands out, even when viewed from the bleachers.

What if you’re organizing a charity run and want participants to have memorable keepsakes for the event? Or you’re part of a marathon team that wants to stand out from the crowd? DTG printing is your solution. With this technique, you can create a variety of vibrant, detailed, and individualized sportswear items that look fantastic and last long.

But one of the biggest advantages of DTG printing when it comes to sportswear is the freedom it offers. It’s a game-changer, allowing you to move beyond the traditional limitations of custom sportswear. You’re no longer restricted to blocky, single-color designs. With DTG printing, you can turn custom sportswear into wearable works of art.

If you’re into showcasing your personality or your team spirit, this is your golden ticket. It’s a method that packs in quality, flexibility, and a chance to let your creativity run wild. It’s time to level up your custom sportswear game, don’t you think?

So you might be sitting there wondering, “Hey, this DTG stuff sounds great, but isn’t it complicated?”

Well, like anything worthwhile, there’s a learning curve. But once you get the hang of it, it’s as easy as pie.

While the process of DTG printing itself isn’t overly complex, understanding the machine, software, and the pre-treatment process is crucial. You need to get comfortable with your DTG printer, learn how to maintain it properly and troubleshoot any issues that might crop up.

Plus, you’ll need to get the hang of preparing your designs in the right format for printing.

That said, most modern DTG printers come with comprehensive user manuals, and there’s a wealth of resources online to help you along.

Many manufacturers and suppliers offer training as part of your purchase. It might seem daunting at first, but like riding a bike or baking the perfect loaf of bread, it gets easier with practice.

Brother GTXpro

Brother has been a trusted name in printing for years, and their GTXpro DTG printer doesn't disappoint. It boasts a high print speed, exceptional print quality, and low running costs. Plus, it's got an intuitive user interface that's easy to get the hang of.

Kornit Avalanche HD6

If you're looking at high-volume DTG printing, the Kornit Avalanche HD6 is a workhorse. It offers industrial-level production capabilities, impressive print speed, and high-quality results. It's a bigger investment, but for large businesses or print shops, it could be worth every penny.

Ricoh Ri 1000

For those just starting out in DTG printing or small businesses, the Ricoh Ri 1000 is a great option. It's more affordable than some of the other models but still delivers excellent print quality. It's also user-friendly, with automated maintenance features and easy-to-use software.

%20Ri%203000Ri%206000.png?width=1200&length=1200&name=Anajet%20(Ricoh)%20Ri%203000Ri%206000.png)

Anajet (Ricoh) Ri 3000/Ri 6000

The Anajet Ri 3000 and Ri 6000 printers, now part of the Ricoh family, are also well-regarded in the industry. They're known for their durability, ease of use, and high-quality prints. The Ri 6000 offers a slightly larger print area and faster print speeds than the Ri 3000.

Remember, the best DTG printer for you depends on your specific needs, including your budget, production volume, and quality requirements. Before making a decision, make sure to do your homework, compare different models, and consider what fits your situation best.

1. Sourcing the right software

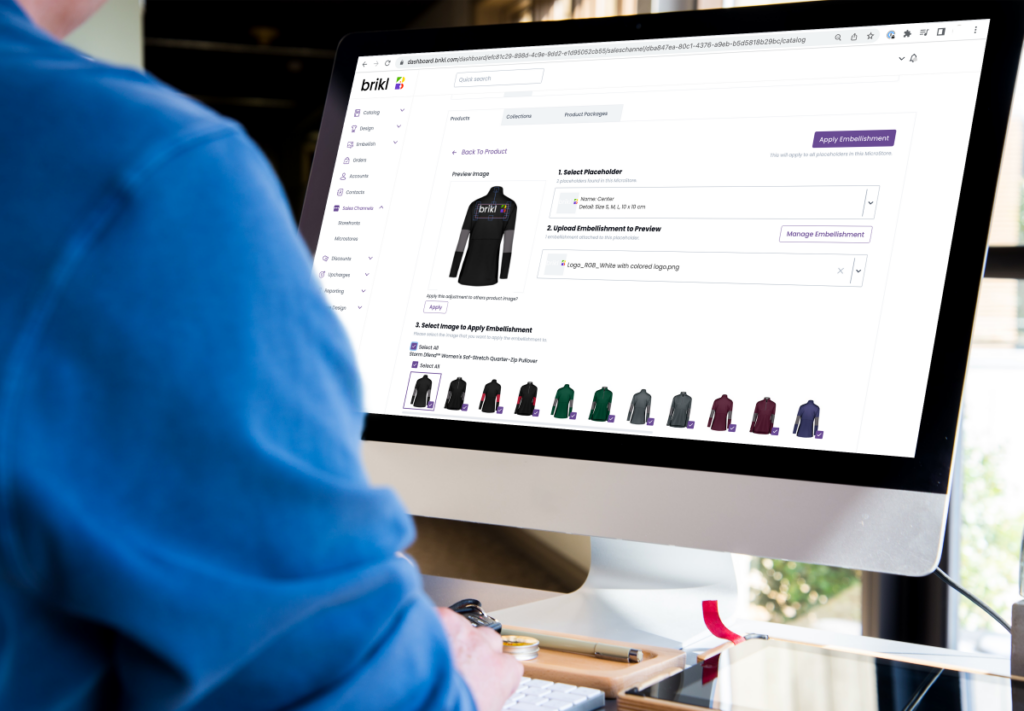

Next, you’ll need the right software to create and format your designs. Most DTG printers come with specific software, so you’ll want to make sure you’re comfortable using it.

2. Get inked

Then, there’s the ink. DTG printers use specific types of water-based ink, so you’ll need to stock up on that. And don’t forget about pre-treatment solutions, especially if you’re printing on dark garments.

Of course, you’re also going to need garments to print on. Remember, DTG works best on high-quality, 100% cotton fabrics.

3. Making a lasting impression

Lastly, you’ll need a heat press or tunnel dryer for curing the ink after printing. This step is crucial to make sure your designs are durable and long-lasting.

While DTG printing might seem a bit tricky at first, it’s not rocket science. With the right equipment, a bit of practice, and a dash of patience, you’ll be cranking out high-quality, custom garments in no time.

In the world we live in today, sustainability is not just a buzzword; it’s a necessity. And when it comes to DTG printing, there’s good news on that front!

Firstly, DTG printers use water-based inks, which are typically more eco-friendly than the plastisol inks used in traditional screen printing. These inks are non-toxic, safer for the environment, and safer for the consumer.

Also, DTG printing produces less waste compared to other methods. There’s no need for screens or transfers, which means less material ends up in the trash. Plus, since it’s a digital process, you only print what you need — no excess inventory ending up in a landfill.

Another point in favor of DTG’s sustainability is the on-demand nature of the process. Because it’s fast and efficient, with no minimum order quantity, you can print only what’s needed, when it’s needed. This reduces overproduction and waste, a major problem in the fashion and apparel industry.

Lastly, many DTG printers are designed to be energy efficient, consuming less power than traditional printing equipment.

That being said, there’s always room for improvement. For instance, the pre-treatment process for dark garments can involve chemicals that aren’t the most environmentally friendly. It’s also important to pair DTG printing with sustainable garments — think organic or recycled materials — to truly maximize its eco-friendliness.

So, while DTG printing isn’t perfect, it’s a step in the right direction when it comes to sustainable garment printing. As technology advances, we can expect even more sustainable practices and materials in the future. Every little bit helps when it comes to taking care of our planet.

DING, DING, DING! Alright, let’s get into this tussle. Direct to garment or screen printing? Well, each has its pros and cons.

Let’s talk about screen printing first. It’s the old reliable. It’s been around since the days of the ancient Chinese dynasties, and it’s not going anywhere.

But how does it work?

In screen printing, your design is divided into layers based on color. Each color gets its own stencil or ‘screen.’ After that, ink is pushed through these stencils onto the fabric one color at a time. It’s like a big, messy coloring book. But here’s the thing – the more colors you’ve got, the more complicated and time-consuming the process becomes.

Also, screen printing shines when you’re dealing with large quantities. Since the initial setup can be a bit of a hassle, you don’t want to be doing all that for a handful of shirts. Go big or go home.

Now, onto DTG printing. It’s the new kid on the block. In DTG printing, an image or design is sent directly from a computer to a printer. Imagine your regular office printer but with a T-shirt instead of paper.

DTG printers can spray tiny droplets of ink onto the garment, which are then absorbed by the fibers. This means you can have highly detailed, vibrant prints, no matter how many colors you’re dealing with. Plus, there’s no setup time like in screen printing, so it’s perfect for small batches or one-off prints.

However, DTG isn’t as cost-effective as screen printing for large batches. It also doesn’t work as well on dark-colored garments unless you apply a pre-treatment.

In the grand scheme of things, choosing between DTG and screen printing comes down to your specific needs. If you’re looking for a detailed, colorful design and have a small batch, DTG might be the way to go. If you’re planning to print a massive number of shirts with a simple design, then screen printing might be your best bet.

So you’ve got your kit, you’ve got your kaboodle, and you’re ready to print.

First things first, you need a digital design. This is where your creative juices come into play. You could go with a funny slogan, a vibrant graphic, or maybe even a photo of your beloved dog – the sky’s the limit. Whatever it is, make sure you’ve got it ready in a digital format, like a high-resolution JPEG or PNG.

Now, once you’ve got that masterpiece, it’s time to prep your garment. Before any ink hits the fabric, the garment goes through a process called pretreatment. It’s kind of like priming a wall before you paint it. This is done using a special solution that ensures the ink adheres properly to the garment.

With the garment prepped and ready, it’s loaded onto your DTG printer. Here’s where things get interesting. Instead of using stencils or screens like traditional printing methods, the DTG printer reads your digital image and prints it directly onto the garment, just like your printer at home would print onto paper.

As mentioned, the printer sprays tiny droplets of ink onto the fabric, building up your design layer by layer. The level of detail it can achieve is pretty astounding.

The final part of the process is to cure the ink. Once the design is printed, the garment is heat-pressed or put through a tunnel dryer. This process is essentially baking the design into the fabric. It’s like making sure the design doesn’t go anywhere, even after multiple trips through the washing machine.

And voila! You’ve gone from a digital artwork to a wearable masterpiece. You’re now in the business of making custom apparel that looks good and lasts forever.

What’s so great about DTG printing, you ask? Well, if the rest of this article hasn’t told you that so far, let’s turn things up a notch.

Firstly, the quality is amazing. DTG printers offer a level of detail that would make a fine artist blush. So if you’re going for a detailed design, this is your best bet.

Secondly, there’s no limit to the number of colors you can use. Remember the screen printing analogy? Forget about that old-school, one-color-at-a-time nonsense. With DTG, you can use a gazillion colors if you want.

Finally, there’s the turnaround time. DTG printing doesn’t require a lot of preparation. It’s like fast food for custom clothing — only it’s better for you.

So there you have it. That’s DTG printing in a nutshell. It’s a top-tier option for custom apparel, offering high quality and great versatility. Whether you’re an artist, a small business owner, or just someone looking to print a cool design on a shirt, DTG can be your new best friend.

Want to know more about DTG and how online stores can help you display your custom creations with pride? How about how online stores can help you drive sales? We’ve got you! Chat to us today.